Terametrix探讨了瓶子和预成型件层的离线Terahertz(THz)测量

制造商使用在线过程控制测量和离线质量控制测量。离线测量通常是那些需要额外时间的测量,但通常会显示在线无法获得的细节。在此过程中早期的更多深入研究可以实际降低制造新产品的设置时间(可能是多数量),并有助于表征产品规格(例如,壁厚)和新材料的有效性(塑料的替代品)。bob综合平台

离线测量和优化方法可以完全不同,通常提供更详细的测量或分析,可用于改善产品或改善过程。一个例子是在多层结构中的全瓶厚度映射的快速(<40秒)产生,包括多层结构。bob综合平台目前的方法需要在瓶子上的几个地方消耗破坏性测量。但是,A.T-ray 5000terahertz measurement system running at 1 kHz deployed at-line or off-line could provide the full bottle detailed information necessary to significantly shorten the startup cycle for these complex multi-layer bottles and improve the layer thickness consistency of the product.

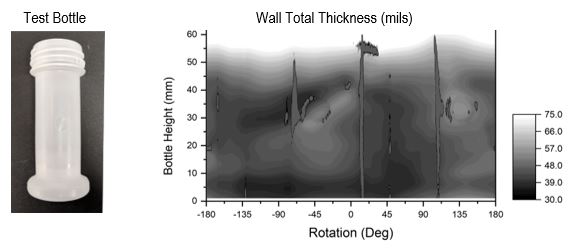

In the example case here, a multilayer bottle is placed on a Z - Θ rotation stage that can rotate around and translate along the length of the bottle. The total wall thickness, as well as each individual layer can then be mapped.

瓶子的某些区域不提供测量,例如测量。沿接缝和高弯曲注射点。在上面的图像中,瓶子的圆柱形部分以这种方式映射。整个扫描需要大约40秒,但这取决于所需的分辨率。

产品的关bob软件苹果怎么下载键结构(例如,擅长er layers in pharmaceutical bottles and fuel tanks), confirmation of presence and proper manufacture of the structure is essential. The absence, gaps or insufficient thickness of an internal barrier layer can be extremely problematic. Spot checks are a common practice, but full product scanning can both be used for QA purposes and product optimization / cost savings purposes. The ability to routinely and easily make such whole product scans quickly, without requiring any couplant, and measuring both clear and opaque materials further increases the value of the measurement.

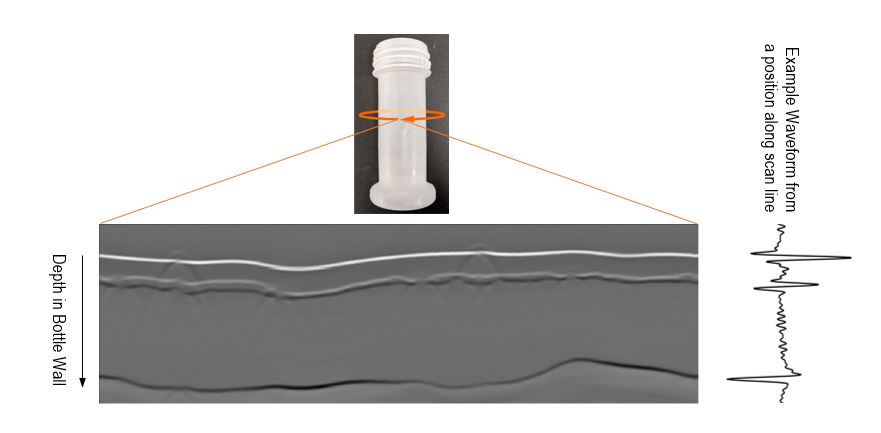

即使非常快速(1 - 2秒)简单的扫描也可以提供完整的产品图片。物体的简单线性扫描创建B扫描,这是沿扫描线的产品的横截面图像。图像结果可以清楚地显示不正确的层结构。例如,扫描线可以是圆瓶周围的圆周。B扫描图像沿扫描线展示了总和层厚度值的变化。bob综合平台

The grey scale of the lines in the image correspond to the polarity and amplitude of the reflection peaks in the waveforms along the scan line. The Y-axis of the B-Scan is time of the waveform which corresponds to depth into the bottle wall.

In addition to thickness variation, additional features such as potential gaps in the center barrier layer can be seen.

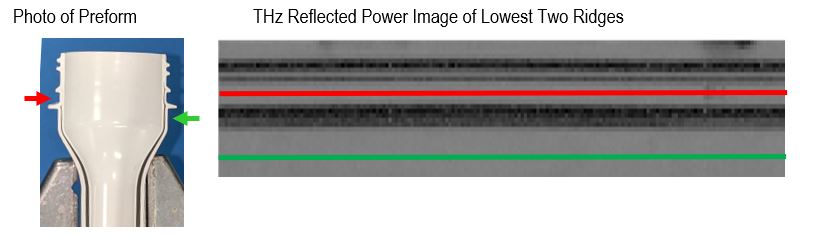

THz的类似离线应用是用于吹塑的预制件的测量,尤其是内层的检测。预制件中的一个层,加入炭黑,可以用作遮光层。这层延伸在帽下方至关重要。由于导致THz脉冲的反射的材料的轻微导电,THz对炭黑敏感。

An important measurement on the preform is the confirmation that the Black layer reaches sufficient far into the screw cap end for all 360 degrees around the sample. For the sample pictured below, it can be seen that the Black layer is present at the two locations below the lower ridge (Green arrow), but not at both locations above the ridge (Red arrow).

沿着绿色和红色箭头的高度的预制件的圆周的B扫描(横截面图)有助于证明黑层的存在或不存在。

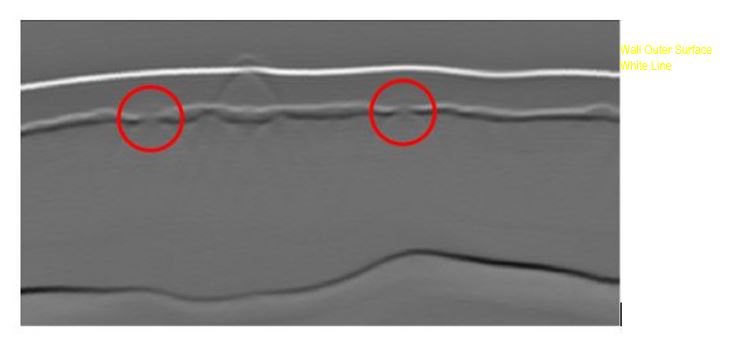

In the B-Scans, the bright white line near the top of the images is the outer surface of the preform. The dark solid Black line near the bottom is the inner surface. The lower intensity light / dark lines in between these are reflections for interior layers.

Note that for the scan at the Green arrow position, the interiors reflections can be seen as a clear layered structure between the White Top line and Black Bottom line.

但是,对于红色箭头处的完全扫描,只能看到一致的层结构对于图像的开始和结尾。这两个区域之间的层结构的损失是指黑层不会延伸到样品的所有360º的红色箭头位置。

This type of THz measurement, enabled by theT-ray 5000和伴随运动硬件,是一种强大的工具,用于检查和评估瓶子和预制件。通过以这种方式测量瓶子,制造商可以更快地优化新的生产线,而且还可以在持续生产中保持高质量的产品。