Thermal Mapping of Batteries

The performance and lifecycle costs of electric vehicles and hybrid vehicles depend heavily on battery functionality. The thermal design and operation of battery modules and battery packs is critical to the deployment of economical, safe and reliable electric powertrains.

The performance and lifecycle costs of electric vehicles and hybrid vehicles depend heavily on battery functionality. The thermal design and operation of battery modules and battery packs is critical to the deployment of economical, safe and reliable electric powertrains.

A Better Alternative to RTDs and Thermocouples

Fiber optic sensors have several inherent benefits that make them ideal for thermal analysis of batteries and other energy storage technologies, including:

- Dielectric — immunity to EMI and high voltages

- Corrosion-resistant

- Non-conductive optical fiber

- Multipoint and distributed thermal measurements

- 快热response.

Fiber optic sensors can be embedded into battery packs and make direct contact with battery cells and contacts, without any concern for causing short circuits or being affected by high voltages and currents.

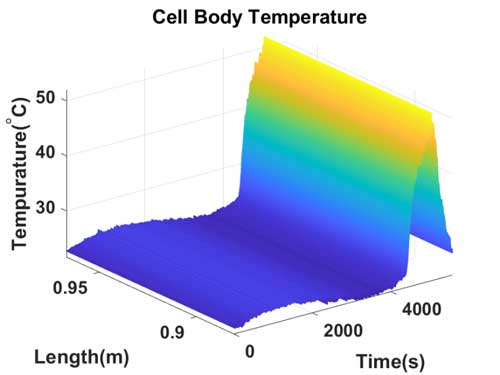

Luna’s fiber optic sensing solutions are inherently multipoint or distributed, allowing the monitoring of temperature at many more locations using only a single, very small optical fiber. Luna’s high-definition fiber optic sensing (HD-FOS) technology provides essentially continuous temperature measurements along the fiber, supplying much more thermal data than possible with conventional systems using RTDs and thermocouples.

Additionally, embedded fiber optic sensors have a very low thermal mass and exhibit a very fast response to rapid temperature increases for early detection of overheating and thermal runaway events.

Featured Products

High-Definition Distributed Fiber Optic Sensing

High-Definition Sensors